The product we are introducing is High Quality molecular sieves, 4a cas 70955 - 01 - 0 With Best Price. Molecular sieve 4A is a type of crystalline aluminosilicate with a three - dimensional network structure. The "4A" indicates that its pore size is approximately 4 angstroms, which is capable of adsorbing molecules with a kinetic diameter of less than 4 angstroms.

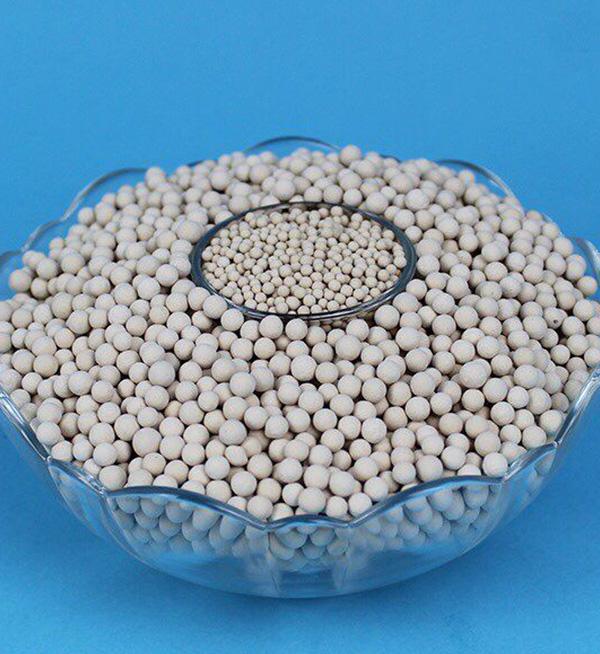

It has a high surface area, typically around 500 - 800 m²/g. This large surface area provides many active sites for adsorption. The bulk density is usually in the range of 0.6 - 0.8 g/mL, and its moisture content is generally less than 1.5%. The chemical formula of 4A molecular sieve is Na₂O·Al₂O₃·2SiO₂·4.5H₂O. It is available in different physical forms such as beads, pellets, and powders to meet various application requirements.

High Quality molecular sieves 4A have a wide range of applications. In the gas and liquid drying process, they are highly efficient desiccants. For example, in the natural gas industry, they can remove water vapor from natural gas to prevent pipeline corrosion and blockage caused by hydrate formation. In the air separation process, they can be used to dry and purify air, ensuring the quality of the separated oxygen and nitrogen.

They are also used in the separation of molecules in the petrochemical industry. Since the pore size of 4A molecular sieve is very specific, it can selectively adsorb certain molecules based on their size. For instance, it can separate normal paraffins from branched - chain and cyclic hydrocarbons in the petroleum refining process, which is crucial for improving the quality of gasoline and diesel.

In the refrigeration and air - conditioning industry, 4A molecular sieves are used as adsorbents for refrigerants. They can adsorb trace amounts of water in the refrigerant system, preventing water from freezing in the expansion valve and causing system failure.

When using High Quality molecular sieves 4A, first, it is necessary to select the appropriate physical form according to the application. If it is for a fixed - bed adsorption process, beads or pellets are usually preferred. For some powder - mixing processes, powder form can be used.

Before use, the molecular sieve needs to be activated. Activation is usually carried out by heating in a high - temperature environment, typically at 350 - 500°C for 3 - 4 hours under a dry inert gas atmosphere (such as nitrogen). This process can remove the adsorbed water and other impurities, restoring the adsorption capacity of the molecular sieve.

During the adsorption process, the flow rate of the gas or liquid to be treated should be controlled properly. If the flow rate is too high, the contact time between the molecular sieve and the target molecules will be insufficient, resulting in reduced adsorption efficiency. After a period of use, when the adsorption capacity of the molecular sieve is saturated, it needs to be regenerated. Regeneration methods are similar to the activation process, mainly through high - temperature heating and purging with an inert gas.

A large - scale natural gas processing plant was facing a problem of high water content in the natural gas pipeline. The high water content led to frequent corrosion and blockage of the pipeline, which affected the normal operation of the plant and increased maintenance costs. The plant decided to use High Quality molecular sieves 4A for water removal.

First, they installed a fixed - bed adsorption system filled with 4A molecular sieve pellets. The natural gas passed through the fixed - bed at a controlled flow rate. After the installation of the molecular sieve system, the water content in the natural gas decreased significantly, from the original 500 ppm to less than 10 ppm. This greatly reduced pipeline corrosion and blockage problems. The plant also carried out regular regeneration of the molecular sieve to maintain its adsorption performance. After one - year of operation, the plant saved a large amount of maintenance costs and improved the overall efficiency of natural gas processing.

If you have any questions or need further information about High Quality molecular sieves 4A, please feel free to contact us. Our email is info@vivalr.com, and our phone number is (86) 15866781826.

This is William, CEO of Zhishang Chemical Co., Ltd.

Welcome to visit our factory . As the top chemical manufacturer, we have been striving for product quality, innovation , R&D, and customer service for the past 7 years. In the next 10 years or even longer, we are committed to becoming the most reliable chemical supplier in the world , creating a well-known international brand trusted by customers, with the spirit of “one meter wide, ten thousand meters deep”, we continue to focus on product research and development, continue to focus on customer service, continue to improve the supply chain service system, to create a professional chemical supply service team, to achieve win-win long-term cooperation. Please feel free to contact us if you have any questions.