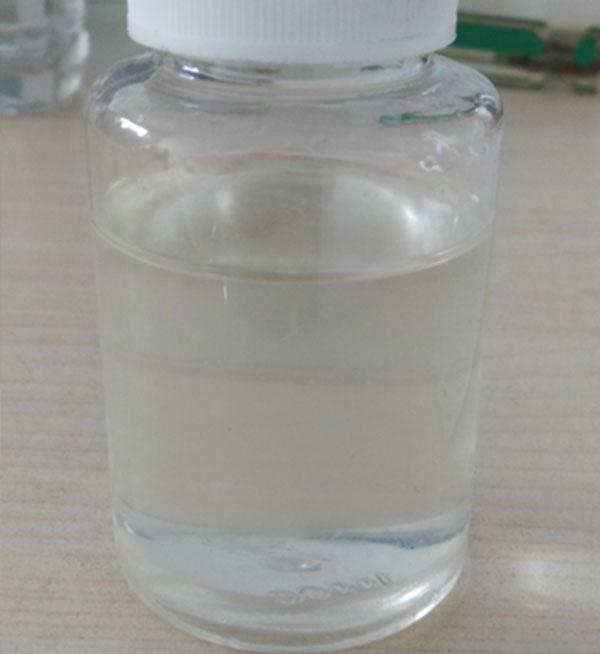

Our Factory Supply Industrial Glutaraldehyde, with the CAS number 111 - 30 - 8, is a high - quality chemical product. It is a colorless or yellowish transparent liquid with a pungent odor. The molecular formula of glutaraldehyde is C₅H₈O₂, and the molecular weight is approximately 100.12 g/mol. It is soluble in water, ethanol, and ether. Glutaraldehyde usually exists in two forms: monomeric and polymeric. The purity of our industrial - grade glutaraldehyde can reach up to 50% or even higher, which meets the strict requirements of various industrial applications.

Industrial glutaraldehyde has a wide range of uses. In the medical field, it is a powerful disinfectant and sterilizer. It can inactivate a variety of microorganisms, including bacteria, fungi, and viruses, making it suitable for disinfecting medical devices, such as endoscopes and surgical instruments. In the leather industry, glutaraldehyde is used as a tanning agent. It can cross - link the collagen fibers in leather, improving the leather's strength, flexibility, and resistance to heat and water. In the textile industry, it is used for anti - shrinkage and crease - resistant finishing of fabrics, enhancing the fabric's dimensional stability and durability. Additionally, it is also used in the oil and gas industry as a biocide to control the growth of bacteria in water injection systems and pipelines, preventing corrosion and blockage.

When using industrial glutaraldehyde, proper safety precautions should be taken. Wear appropriate personal protective equipment, such as gloves, goggles, and protective clothing. In the medical disinfection process, the appropriate concentration of glutaraldehyde solution should be prepared according to the type of medical device. Usually, a 2% - 3% glutaraldehyde solution is used for soaking disinfection, and the soaking time is generally 2 - 10 hours. After disinfection, the medical device should be thoroughly rinsed with sterile water to remove the residual glutaraldehyde. In the leather tanning process, glutaraldehyde is added to the tanning bath at a certain ratio, and the tanning process usually lasts for several hours to ensure sufficient cross - linking of collagen fibers. In the textile finishing process, glutaraldehyde is applied to the fabric through padding or spraying methods, followed by heat treatment to fix it on the fabric.

Case 1: Medical Device Disinfection

A large - scale hospital was facing problems with the disinfection of its endoscopes. The traditional disinfection method was not effective enough to eliminate some stubborn bacteria and viruses. After switching to using our industrial glutaraldehyde, they prepared a 2% glutaraldehyde solution and soaked the endoscopes for 4 hours. Subsequent microbiological tests showed that the disinfection rate reached over 99.9%, effectively reducing the risk of cross - infection among patients.

Case 2: Leather Tanning

A leather factory was looking for a more environmentally friendly and high - quality tanning agent. They adopted our glutaraldehyde in the tanning process. By adding glutaraldehyde at a ratio of 2% to the tanning bath and tanning for 6 hours, the resulting leather had improved physical properties. The tensile strength increased by 20%, and the leather became more flexible and resistant to water, meeting the high - end market requirements.

If you have any questions or need further information about our Factory Supply Industrial Glutaraldehyde, please feel free to contact us. Our email is info@vivalr.com, and our phone number is (86) 15866781826.

This is William, CEO of Zhishang Chemical Co., Ltd.

Welcome to visit our factory . As the top chemical manufacturer, we have been striving for product quality, innovation , R&D, and customer service for the past 7 years. In the next 10 years or even longer, we are committed to becoming the most reliable chemical supplier in the world , creating a well-known international brand trusted by customers, with the spirit of “one meter wide, ten thousand meters deep”, we continue to focus on product research and development, continue to focus on customer service, continue to improve the supply chain service system, to create a professional chemical supply service team, to achieve win-win long-term cooperation. Please feel free to contact us if you have any questions.