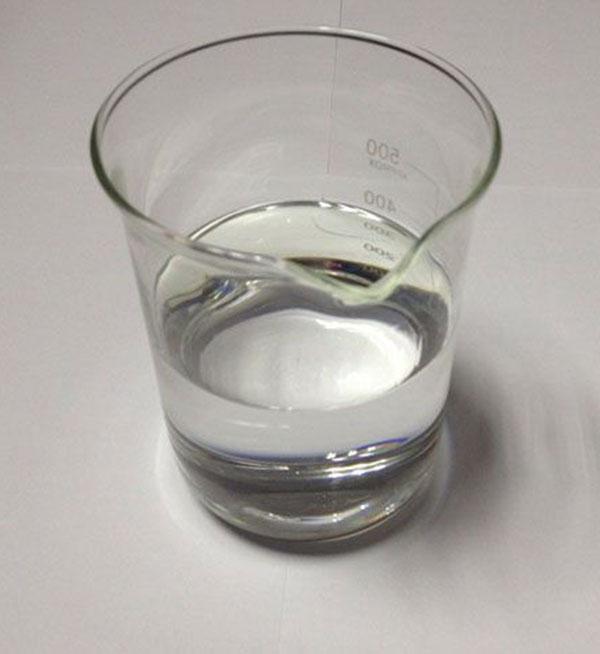

Propylene Glycol Monomethyl Ether Acetate (PGMEA), with the CAS number 108 - 65 - 6, is a colorless, transparent, and flammable liquid. It has a mild and pleasant odor. The chemical formula of PGMEA is C₆H₁₂O₃, and its molecular weight is approximately 132.16 g/mol.

PGMEA has good solubility in a variety of organic solvents, such as alcohols, ketones, and ethers. Its boiling point is around 146 - 14醋酸的溶解度为1.97 g/100 mL at 20°C. It is a versatile chemical intermediate with low viscosity and high evaporation rate.

PGMEA is widely used in different industries. In the coatings industry, it is an excellent solvent for high - quality industrial coatings, automotive coatings, and architectural coatings. It can improve the leveling property, gloss, and adhesion of the coatings, resulting in a smooth and high - quality finish.

In the electronics industry, PGMEA is used as a photoresist solvent in the semiconductor manufacturing process. It can effectively dissolve photoresist polymers and help to form precise patterns on silicon wafers during photolithography.

It is also used in the printing ink industry. It can enhance the fluidity and drying speed of the ink, making the printed images clearer and more vivid. Additionally, PGMEA is used in the production of cleaning agents, where it can dissolve greases, oils, and other contaminants.

When using PGMEA in the coatings industry, it should be added to the coating formulation at the appropriate ratio according to the specific requirements of the coating. Usually, it is added during the mixing process of the coating components. The temperature and mixing time should be controlled to ensure uniform dispersion.

In the electronics industry, when using it as a photoresist solvent, strict environmental conditions should be maintained. The concentration of PGMEA in the photoresist solution should be accurately controlled. Operators should wear appropriate personal protective equipment, such as gloves and goggles, to avoid contact with the skin and eyes.

For the printing ink industry, PGMEA should be added slowly to the ink during the production process, and continuous stirring is required to ensure homogeneity. When using it in cleaning agents, the appropriate dilution ratio should be determined according to the type and degree of contamination.

Case 1: A coatings manufacturer was facing the problem of poor leveling and low gloss in their automotive coatings. After adding PGMEA to their coating formulation at an optimal ratio of 15%, they found that the leveling property of the coatings improved significantly. The surface of the painted cars became smoother, and the gloss increased by 20%. This led to higher customer satisfaction and an increase in market share.

Case 2: In a semiconductor manufacturing plant, the previous photoresist solvent was causing some pattern - definition problems during photolithography. After switching to PGMEA, the precision of the patterns on the silicon wafers improved. The defect rate decreased from 5% to 1%, resulting in higher production yields and lower production costs.

Case 3: A printing company was struggling with slow - drying inks, which affected their production efficiency. By adding PGMEA to their ink formulation, the drying speed of the inks increased by 30%. This allowed the company to increase its production volume and reduce the waiting time between printing processes.

If you have any questions about Propylene Glycol Monomethyl Ether Acetate, please feel free to contact us. Our email is info@vivalr.com, and our phone number is (86) 15866781826. We are happy to provide you with more detailed information and technical support.

This is William, CEO of Zhishang Chemical Co., Ltd.

Welcome to visit our factory . As the top chemical manufacturer, we have been striving for product quality, innovation , R&D, and customer service for the past 7 years. In the next 10 years or even longer, we are committed to becoming the most reliable chemical supplier in the world , creating a well-known international brand trusted by customers, with the spirit of “one meter wide, ten thousand meters deep”, we continue to focus on product research and development, continue to focus on customer service, continue to improve the supply chain service system, to create a professional chemical supply service team, to achieve win-win long-term cooperation. Please feel free to contact us if you have any questions.