Poly(tetrahydrofuran), with the CAS number 25190 - 06 - 1, is a high - quality product offered by our factory at a low price. It is a linear polyether glycol, also known as polytetramethylene ether glycol (PTMEG). The molecular formula of poly(tetrahydrofuran) is (C₄H₈O)ₙ, and its structural formula shows a repeating tetramethylene ether unit.

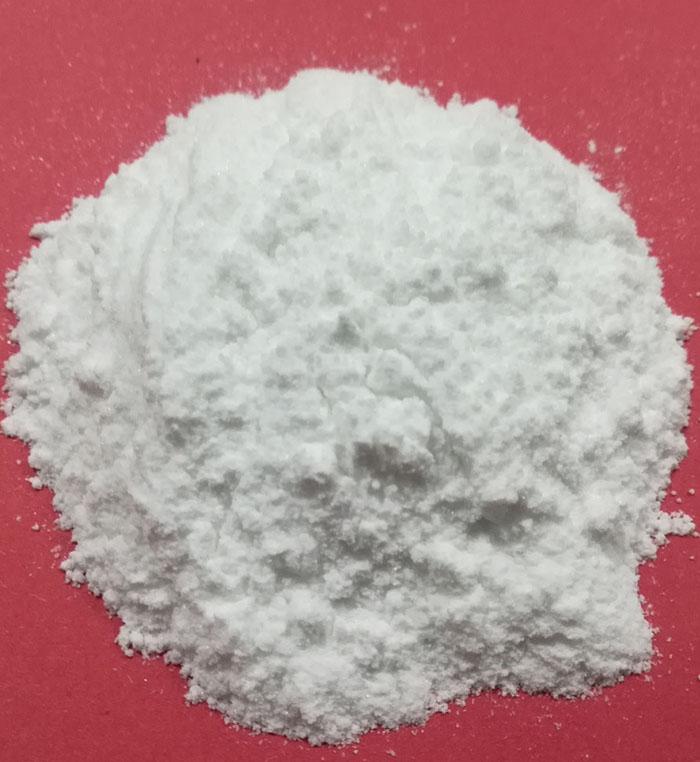

The physical properties of poly(tetrahydrofuran) are notable. It is a white to off - white waxy solid at room temperature, but it can become a clear, colorless liquid when heated slightly. It has good solubility in common organic solvents such as acetone, ethanol, and chloroform. The average molecular weight of our factory - supplied poly(tetrahydrofuran) can be customized according to customer requirements, typically ranging from several hundred to several thousand. This flexibility in molecular weight allows for a wide range of applications.

Poly(tetrahydrofuran) has a diverse range of applications across multiple industries. In the polyurethane industry, it is a key raw material for the production of high - performance polyurethanes. When combined with diisocyanates, it forms polyurethane elastomers that are used in automotive parts, such as seals and gaskets, due to their excellent abrasion resistance, flexibility, and low - temperature performance.

In the textile industry, poly(tetrahydrofuran) is used to produce spandex fibers. Spandex, also known as elastane, is highly elastic and is widely used in sportswear, swimwear, and lingerie. The use of poly(tetrahydrofuran) in spandex production imparts superior stretch and recovery properties to the fibers.

It also finds applications in the production of coatings and adhesives. Poly(tetrahydrofuran) - based coatings offer good adhesion, chemical resistance, and flexibility, making them suitable for various substrates, including metals, plastics, and wood. In adhesives, it helps to improve the bonding strength and flexibility of the adhesive joints.

When using poly(tetrahydrofuran), it is important to handle it with care. As it is a solid at room temperature, it needs to be melted before use. The melting process should be carried out in a well - ventilated area using appropriate heating equipment. The recommended melting temperature is usually between 40 - 60°C, depending on the specific molecular weight of the product.

During the production process, accurate measurement of poly(tetrahydrofuran) is crucial. It should be mixed with other reactants in the correct proportions according to the specific formulation. For example, in the production of polyurethanes, the ratio of poly(tetrahydrofuran) to diisocyanate needs to be carefully controlled to achieve the desired properties of the final product.

After use, any remaining poly(tetrahydrofuran) should be stored properly in a sealed container in a cool, dry place to prevent oxidation and contamination.

Case 1: Automotive Industry

A major automotive parts manufacturer used our factory - supplied poly(tetrahydrofuran) to produce seals for car engines. By using poly(tetrahydrofuran) - based polyurethane elastomers, the seals showed excellent resistance to engine oil, fuel, and high temperatures. This led to a significant reduction in seal failures, improving the overall reliability of the engines. The manufacturer reported an increase in customer satisfaction due to the longer service life of the engines.

Case 2: Textile Industry

A textile company incorporated poly(tetrahydrofuran) into their spandex production process. The resulting spandex fibers had a higher elastic recovery rate compared to traditional spandex. The sportswear made from these fibers provided better comfort and fit for athletes. The company was able to gain a competitive edge in the market and increase their market share due to the superior quality of their products.

If you have any questions or need more information about our Factory Supply Poly(tetrahydrofuran) CAS 25190 - 06 - 1, please feel free to contact us:

Email: info@vivalr.com

Phone: (86) 158667818

This is William, CEO of Zhishang Chemical Co., Ltd.

Welcome to visit our factory . As the top chemical manufacturer, we have been striving for product quality, innovation , R&D, and customer service for the past 7 years. In the next 10 years or even longer, we are committed to becoming the most reliable chemical supplier in the world , creating a well-known international brand trusted by customers, with the spirit of “one meter wide, ten thousand meters deep”, we continue to focus on product research and development, continue to focus on customer service, continue to improve the supply chain service system, to create a professional chemical supply service team, to achieve win-win long-term cooperation. Please feel free to contact us if you have any questions.