User Guide for High Quality polyglycerol - 10 laurate cas 34406 - 66 - 1 With Best Price

1. Basic Information and Parameters

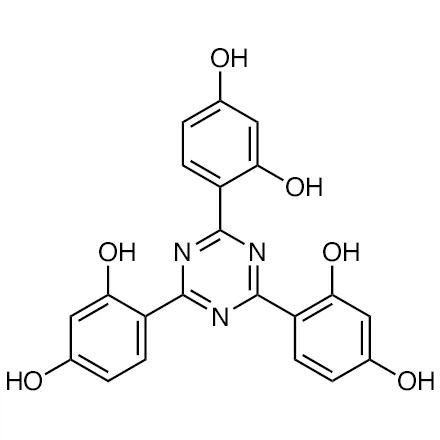

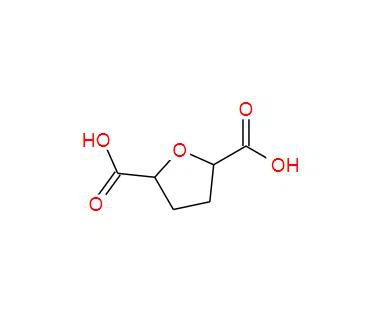

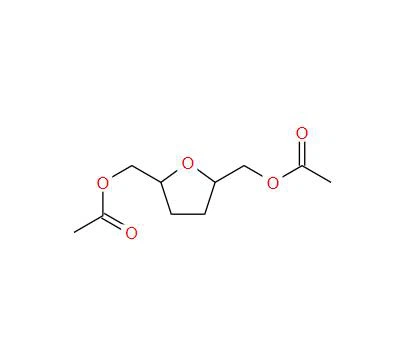

Product Name: High Quality polyglycerol - 10 laurate cas 34406 - 66 - 1 With Best Price

CAS Number: 34406 - 66 - 1

Polyglycerol - 10 laurate is an ester formed from polyglycerol and lauric acid. It is a non - ionic surfactant with excellent emulsifying, dispersing, and solubilizing properties. The product usually appears as a light - yellow to amber viscous liquid or semi - solid at room temperature. It has good stability in a wide range of pH values (usually from 4 - 10) and is compatible with many other surfactants and additives. Its hydrophilic - lipophilic balance (HLB) value typically ranges from 12 - 16, which makes it suitable for various applications where both water - based and oil - based systems need to be stabilized.

2. Product Uses

In the food industry, polyglycerol - 10 laurate is used as an emulsifier and stabilizer. It can prevent oil and water phases from separating in products such as salad dressings, mayonnaise, and ice cream, improving the texture and shelf - life of these products. In the cosmetic and personal care industry, it is applied in creams, lotions, and hair care products. It helps to mix oil and water components evenly, provides a smooth and pleasant texture, and enhances the moisturizing effect. In the pharmaceutical industry, it can be used as an excipient in drug formulations to improve the solubility and stability of poorly soluble drugs.

3. Product Usage

When using polyglycerol - 10 laurate in the food industry, it should be added during the mixing process of the oil and water phases. The recommended dosage usually ranges from 0.1% - 2% depending on the specific product and the desired emulsifying effect. In the cosmetic industry, it can be added to the oil phase or water phase according to the formulation requirements. It is usually heated and mixed with other components at a temperature of 60 - 80°C to ensure uniform dispersion. In the pharmaceutical industry, it should be used in strict accordance with the pharmaceutical formulation and production process requirements, and the dosage should be determined based on the characteristics of the drug and the formulation design.

4. Detailed Product Use Cases

Case 1: In a salad dressing production. A food company was facing the problem of oil - water separation in their salad dressing, which led to an unappealing appearance and short shelf - life. After adding 0.5% polyglycerol - 10 laurate during the emulsification process, the oil and water phases remained well - mixed. The salad dressing had a smooth and homogeneous texture, and its shelf - life was extended by several weeks.

Case 2: In a skin cream formulation. A cosmetic brand wanted to improve the moisturizing effect and texture of their skin cream. By adding 1.5% polyglycerol - 10 laurate to the oil phase and then emulsifying it with the water phase, the cream became more stable and had a better spreadability. Customers reported that their skin felt more hydrated and soft after using the improved cream.

Case 3: In a pharmaceutical tablet formulation. A pharmaceutical company was developing a new drug with poor solubility. They incorporated 2% polyglycerol - 10 laurate as an excipient in the formulation. The drug's solubility was significantly improved, leading to better bioavailability and more consistent drug efficacy.

5. Contact Information

If you have any questions or need further information about this product, please feel free to contact us:

Email: info@vivalr.com

Phone: (86) 15866781826