Product Name: Factory Supply Bis(lauroyloxy)dioctyltin CAS 3648-18-8 With Best Price

CAS Number: 3648-18-8

Chemical Formula: C40H78O4Sn

Molecular Weight: Approximately 743.72 g/mol

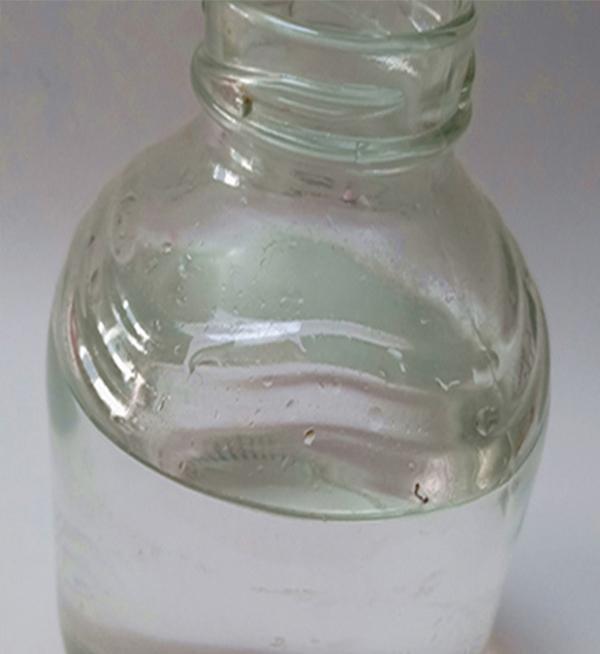

Appearance: It usually appears as a clear to slightly yellowish liquid.

Solubility: It is soluble in common organic solvents such as benzene, toluene, and xylene, but insoluble in water.

Stability: Under normal storage conditions, it is relatively stable. However, it should be kept away from strong oxidizing agents and acids to prevent chemical reactions.

Bis(lauroyloxy)dioctyltin is a highly versatile organotin compound that finds wide - ranging applications in various industries.

It is mainly used as a heat stabilizer in the production of polyvinyl chloride (PVC) products. PVC is prone to thermal degradation during processing, resulting in discoloration, reduced mechanical properties, and the release of hydrogen chloride gas. Bis(lauroyloxy)dioctyltin can effectively capture the hydrogen chloride released during PVC degradation and prevent further chain reactions, thereby improving the thermal stability of PVC products. This allows PVC products to maintain their physical and chemical properties during high - temperature processing and long - term use.

In the rubber industry, it can be used as a catalyst and an accelerator in some rubber vulcanization processes. It can help to improve the vulcanization efficiency, reduce the vulcanization time, and enhance the mechanical properties of the rubber products, such as tensile strength, elongation at break, and tear strength.

The dosage of Bis(lauroyloxy)dioctyltin depends on the specific application and the requirements of the product. In PVC processing, the typical dosage is usually in the range of 0.5% - 3% by weight of the PVC resin. For rubber vulcanization, the dosage needs to be adjusted according to the type of rubber and the vulcanization process, generally ranging from 0.1% - 2%.

When using it in PVC processing, it should be well - mixed with other additives and PVC resin before processing. The processing temperature should be controlled within a reasonable range to ensure the effectiveness of the stabilizer. In rubber vulcanization, it should be added at an appropriate stage of the mixing process to ensure uniform dispersion.

A PVC pipe manufacturing company used Bis(lauroyloxy)dioctyltin as a heat stabilizer. Before using this product, their PVC pipes often showed discoloration and brittleness during high - temperature extrusion. After adding 1.5% Bis(lauroyloxy)dioctyltin by weight of the PVC resin, the pipes had better color stability, and the mechanical properties such as impact strength and tensile strength were significantly improved. The pipes could pass the long - term aging test at high temperatures, and the product quality was greatly enhanced.

A rubber sealing ring manufacturer adopted Bis(lauroyloxy)dioctyltin as a vulcanization accelerator. By adding 0.5% of this product in the rubber compound, the vulcanization time was reduced by 30%. The produced sealing rings had better elasticity, oil resistance, and compression set properties. The production efficiency was improved, and the product performance met the strict requirements of the automotive and aerospace industries.

If you have any questions or need further information about this product, please feel free to contact us.

Email: info@vivalr.com

Phone: (86) 15866

This is William, CEO of Zhishang Chemical Co., Ltd.

Welcome to visit our factory . As the top chemical manufacturer, we have been striving for product quality, innovation , R&D, and customer service for the past 7 years. In the next 10 years or even longer, we are committed to becoming the most reliable chemical supplier in the world , creating a well-known international brand trusted by customers, with the spirit of “one meter wide, ten thousand meters deep”, we continue to focus on product research and development, continue to focus on customer service, continue to improve the supply chain service system, to create a professional chemical supply service team, to achieve win-win long-term cooperation. Please feel free to contact us if you have any questions.