Table of Contents

Product Information

Our product is High Quality Potassium thioacetate with CAS No. 10387 - 40 - 3, offered at the best price. Potassium thioacetate is a white to light - yellow crystalline powder. Its molecular formula is C₂H₃KOS, and the molecular weight is approximately 114.20 g/mol. It has a characteristic odor similar to that of sulfur - containing compounds. The product is highly soluble in water and some common organic solvents, which makes it convenient for various applications.

We ensure the high quality of our potassium thioacetate through strict quality control measures. The purity of our product can reach over 98%, which meets the high - standard requirements of different industries. It is packaged in sealed containers to prevent moisture absorption and oxidation during storage and transportation.

Product Uses

Potassium thioacetate has a wide range of applications in different fields:

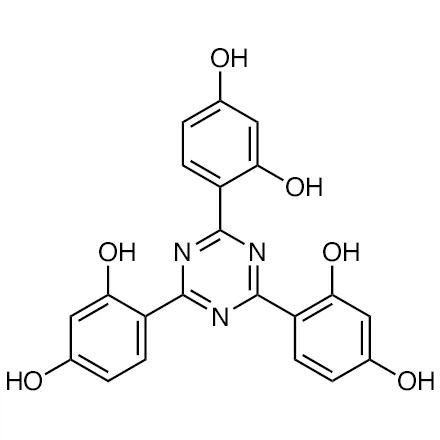

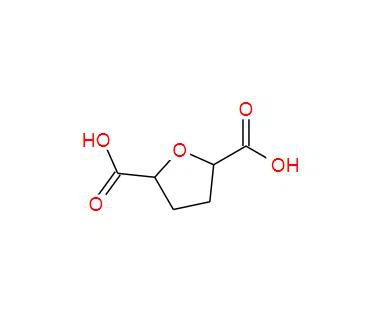

Chemical Synthesis: It serves as an important intermediate in organic synthesis. It can be used to introduce a thioacetyl group into organic molecules. For example, in the synthesis of certain heterocyclic compounds, potassium thioacetate can react with appropriate substrates to form new carbon - sulfur bonds, which is crucial for the construction of complex molecular structures.

Pharmaceutical Industry: In drug development, it can be used to synthesize some sulfur - containing drugs. Sulfur - containing functional groups often play important roles in the biological activities of drugs, such as improving the solubility, stability, and bioavailability of drugs.

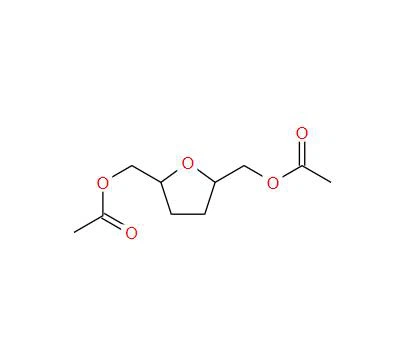

Material Science: It can be used in the preparation of some special - functional materials. For instance, it can participate in the modification of polymer materials, endowing the materials with certain sulfur - related properties, such as improved corrosion resistance or electrical conductivity.

Product Usage

When using potassium thioacetate, it is necessary to follow some safety and operational guidelines.

Storage: Store the product in a cool, dry place away from direct sunlight and heat sources. Keep it in a sealed container to prevent contact with air and moisture, as it may react slowly with water and oxygen over time, affecting its quality.

Handling: Wear appropriate personal protective equipment, such as gloves and safety glasses, when handling potassium thioacetate. Avoid inhalation of dust or vapors. In case of contact with skin or eyes, immediately rinse with plenty of water and seek medical attention if necessary.

Reaction Conditions: In chemical reactions, carefully control the reaction temperature, pH value, and reaction time according to the specific reaction requirements. Usually, reactions involving potassium thioacetate are carried out under mild conditions, but proper stirring and heating may be required in some cases.

Usage Cases

Case 1: Synthesis of a Thio - containing Heterocyclic Compound

In a laboratory setting, a research team aimed to synthesize a novel thio - containing heterocyclic compound for potential anti - cancer activity. They used potassium thioacetate as a key reagent. First, they dissolved a certain amount of potassium thioacetate in an appropriate organic solvent, such as dimethylformamide (DMF). Then, they added the substrate, a halogen - substituted aromatic compound, to the solution. The reaction was carried out at a temperature of around 60 - 70°C for several hours under stirring. After the reaction was completed, they purified the product through column chromatography. The yield of the target heterocyclic compound was relatively high, and the structure was confirmed by nuclear magnetic resonance (NMR) and mass spectrometry (MS). This shows that potassium thioacetate can effectively participate in the synthesis of complex heterocyclic compounds.

Case 2: Modification of a Polymer Material

A materials science group wanted to improve the corrosion resistance of a polymer coating. They incorporated potassium thioacetate into the polymer matrix during the polymerization process. First, they dispersed potassium thioacetate in the monomer solution. Then, the polymerization reaction was initiated under appropriate conditions. The resulting polymer coating showed significantly improved corrosion resistance when tested in a salt - spray environment. The sulfur - containing groups introduced by potassium thioacetate formed a protective layer on the surface of the material, preventing the penetration of corrosive substances