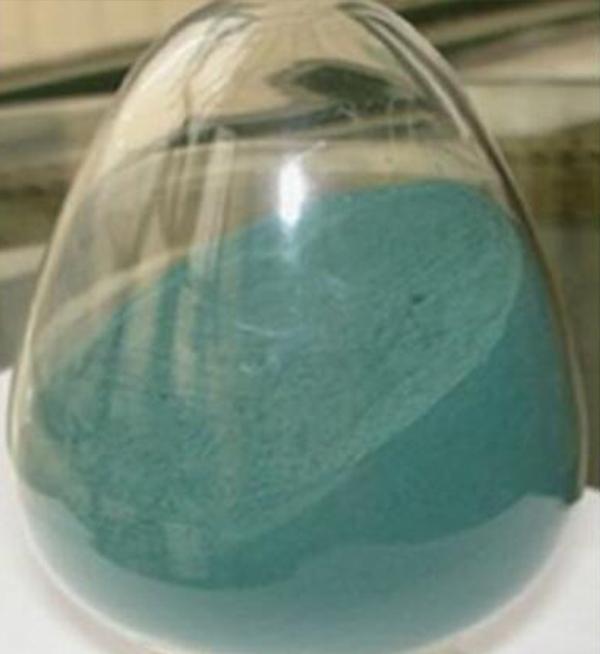

The product is Factory Supply basic chrome sulfate with the CAS number 72993 - 54 - 5. It is offered at the best price. Chrome sulfate is an inorganic compound with specific chemical and physical properties. Chemically, its formula is based on the combination of chromium, sulfur, and oxygen atoms. The compound usually exists in a solid form, often with a characteristic color that can vary depending on its purity and crystal structure.

In terms of purity, our factory - supplied chrome sulfate is of high quality, meeting strict industry standards. It has a well - defined molecular weight and density. These parameters are crucial for its various applications as they determine its reactivity and solubility in different solvents.

Chrome sulfate has a wide range of applications in different industries. In the leather industry, it is used as a tanning agent. Tanning is a process that converts raw hides into leather, making it more durable and resistant to decomposition. Chrome sulfate forms strong chemical bonds with the collagen fibers in the hide, improving its strength and flexibility.

In the textile industry, chrome sulfate is used as a mordant. A mordant is a substance that helps the dye adhere to the fabric more effectively. It forms a coordination complex with the dye molecules, ensuring that the color is fast and does not fade easily. This is particularly important for high - quality textiles that require long - lasting colors.

It also finds applications in the electroplating industry. Chrome sulfate can be used to deposit a layer of chromium on metal surfaces, providing corrosion resistance and a decorative finish. This is commonly seen in the automotive and household appliance industries, where chrome - plated parts are both functional and aesthetically pleasing.

When using chrome sulfate in the tanning process, it is first dissolved in water to form a solution. The concentration of the solution needs to be carefully controlled according to the type and quality of the hides. The hides are then soaked in the solution for a specific period, during which the chrome sulfate penetrates the fibers and forms cross - links.

As a mordant in the textile industry, the fabric is pre - treated with a chrome sulfate solution. The fabric is immersed in the solution at a certain temperature and for a specific time to ensure proper absorption of the mordant. After that, the fabric is dyed using the desired dye. The ratio of chrome sulfate to dye and the processing conditions are important factors to achieve the desired color fastness.

In electroplating, a chrome sulfate solution is used as an electrolyte in an electroplating bath. The object to be plated is connected as the cathode, and a chromium anode is used. An electric current is passed through the bath, causing chromium ions from the chrome sulfate to be deposited on the surface of the object.

Case 1: Leather Tanning

A leather manufacturing company in Italy was facing challenges with the quality of their leather products. The leather was not as durable as they wanted, and the color was fading quickly. They decided to switch to our factory - supplied chrome sulfate. By carefully adjusting the tanning process according to the product's properties, they were able to produce high - quality leather. The leather had improved strength, flexibility, and color fastness. Their products were well - received in the market, and they were able to increase their sales significantly.

Case 2: Textile Dyeing

A textile factory in India was using traditional mordants, but they were not satisfied with the color fastness of their dyed fabrics. After switching to our chrome sulfate, they conducted a series of experiments to optimize the mordanting process. They found that by using the right concentration of chrome sulfate and controlling the processing temperature and time, they could achieve excellent color fastness. Their dyed fabrics passed the strict quality tests, and they were able to expand their export business.

Case 3: Electroplating

An automotive parts manufacturer in the United States was looking for a high - quality chrome plating solution. They started using our chrome sulfate in their electroplating process. The plated parts had a smooth and shiny finish, and the corrosion resistance was significantly improved. This led to a reduction in the number of defective parts and an increase in customer satisfaction.

If you have any questions or need further information about our Factory Supply basic chrome sulfate cas 72993 - 54 - 5, please feel free to contact us. Our email address is info@vivalr.com, and our phone number is (86) 15866781826.

This is William, CEO of Zhishang Chemical Co., Ltd.

Welcome to visit our factory . As the top chemical manufacturer, we have been striving for product quality, innovation , R&D, and customer service for the past 7 years. In the next 10 years or even longer, we are committed to becoming the most reliable chemical supplier in the world , creating a well-known international brand trusted by customers, with the spirit of “one meter wide, ten thousand meters deep”, we continue to focus on product research and development, continue to focus on customer service, continue to improve the supply chain service system, to create a professional chemical supply service team, to achieve win-win long-term cooperation. Please feel free to contact us if you have any questions.